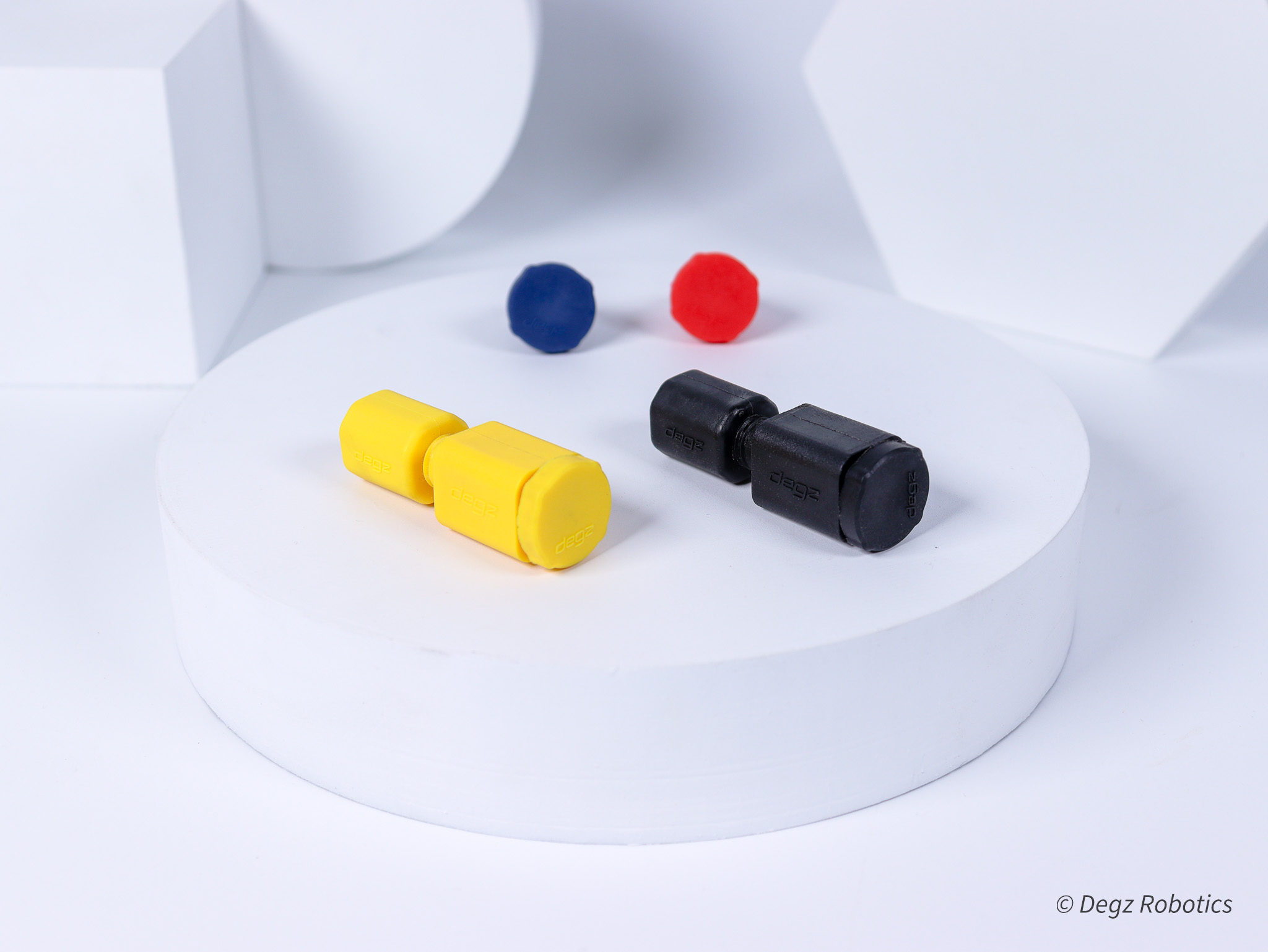

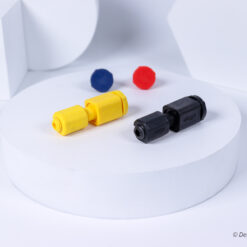

Degz Valve Penetrator is revolutionizing the world of underwater technology. This unique fastener offers exceptional sealing properties even under high pressure, allowing underwater tools to easily overcome even the most demanding tasks. Degz Valve Penetrator redefines safety standards in underwater exploration and operations, keeping durability and performance at the forefront.

Its innovative structure offers maximum safety and effectiveness in all kinds of underwater activities, while the material quality promises durability in the long term. Saving time with easy assembly, Degz Valve Penetrator offers a user-friendly experience. This product, which can adapt to various application areas, is preferred in a wide range from underwater robots to research platforms, sealed electronic containers.

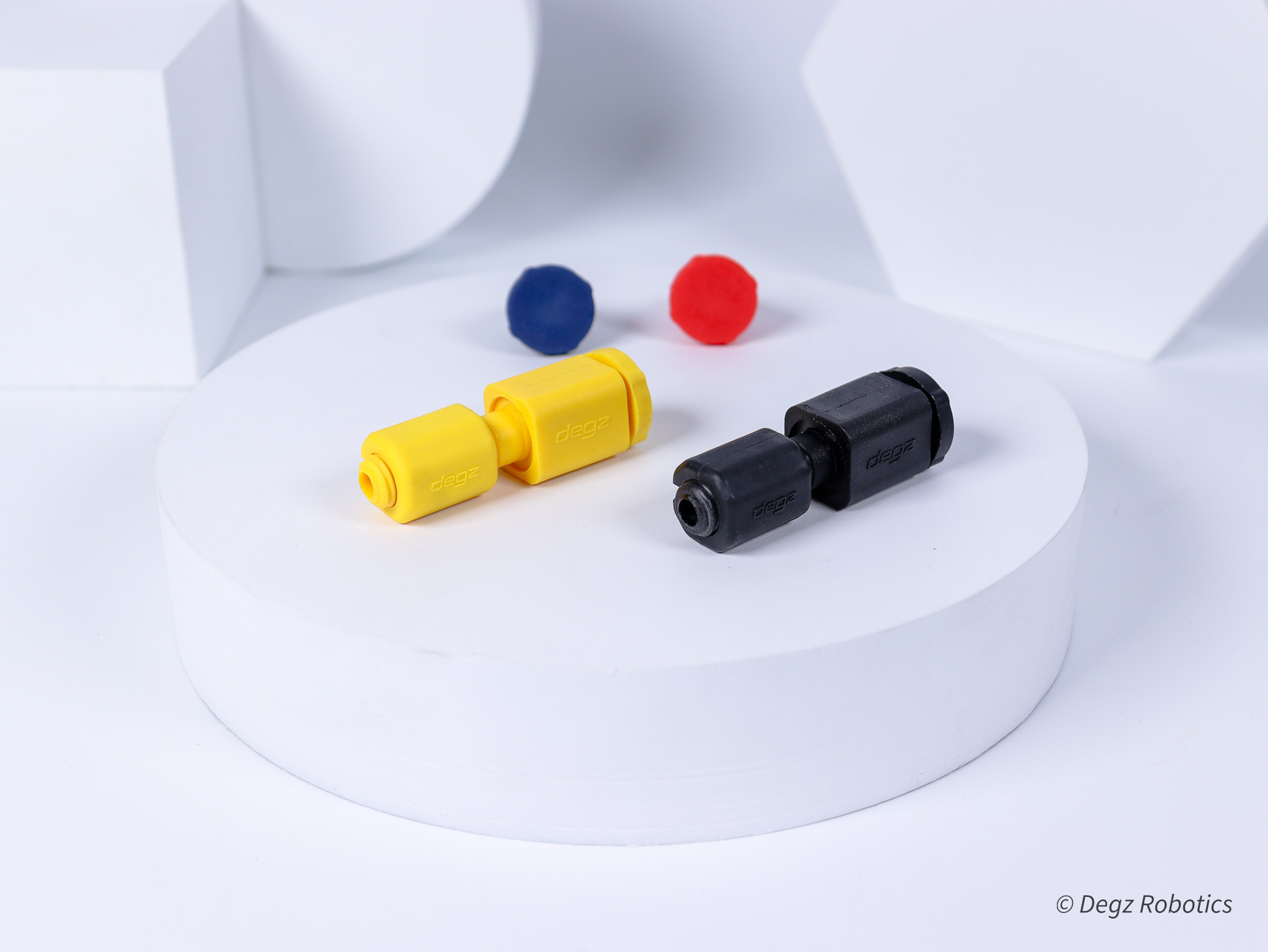

Easy Installation and Reliable Seal

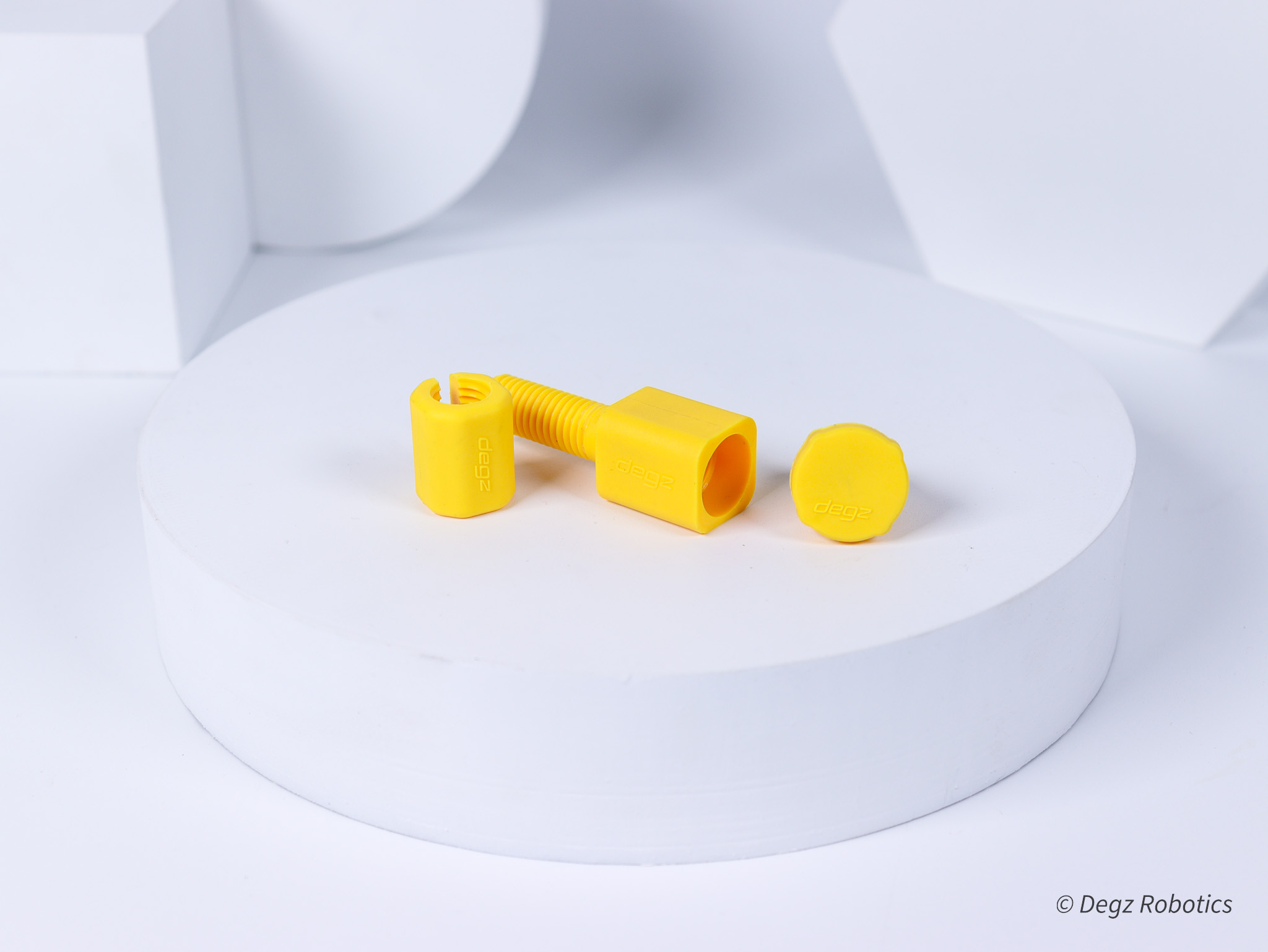

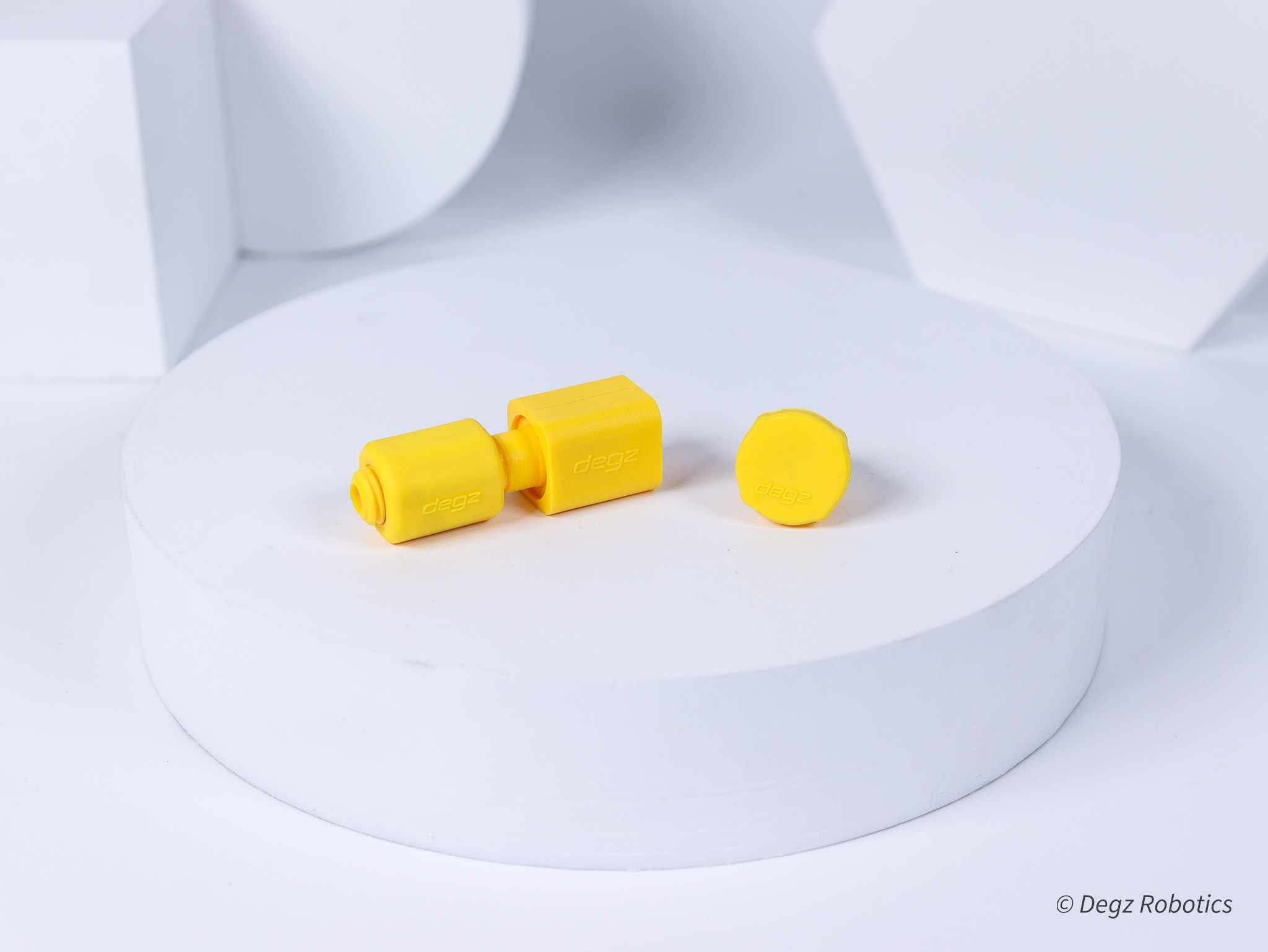

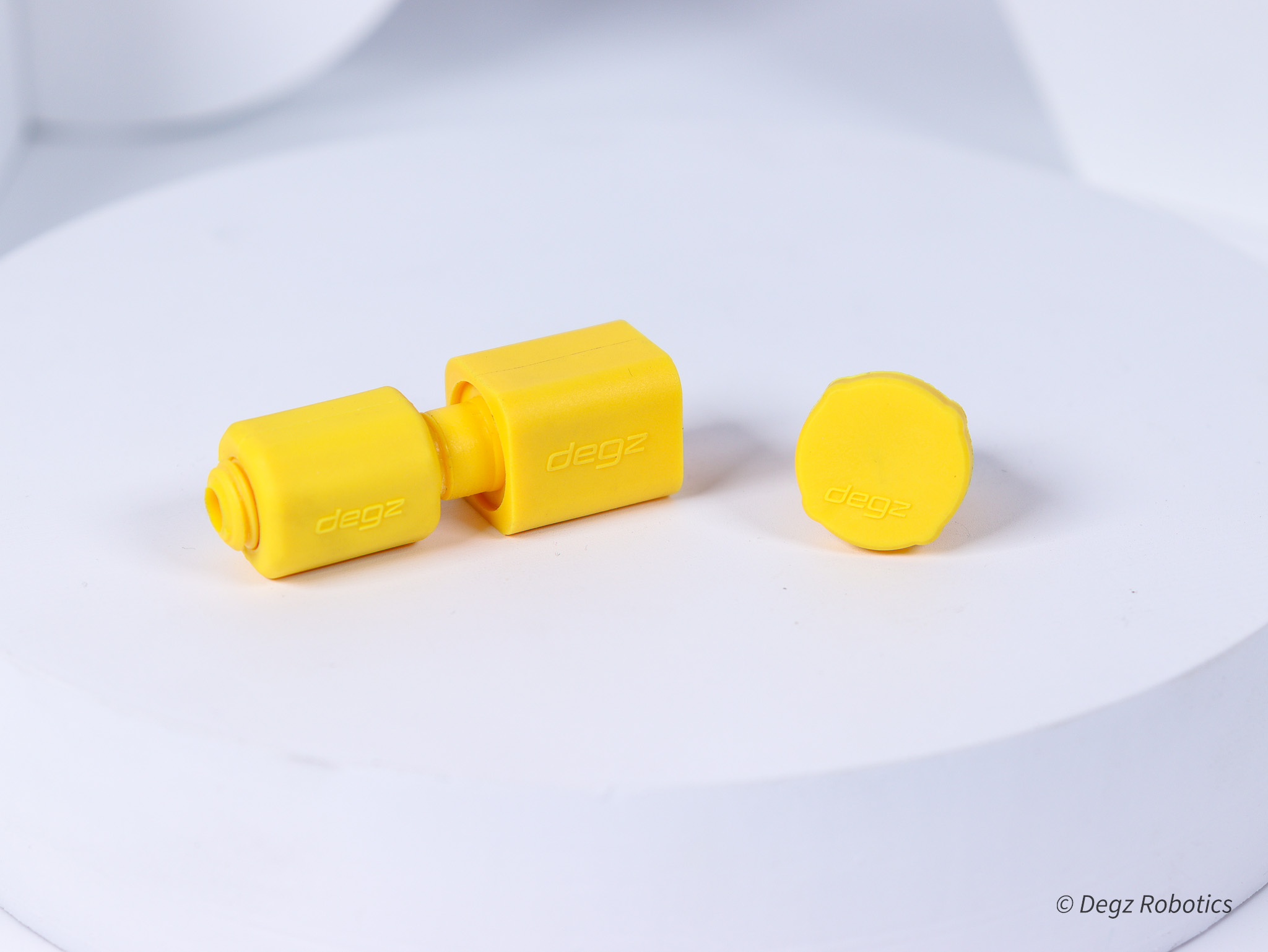

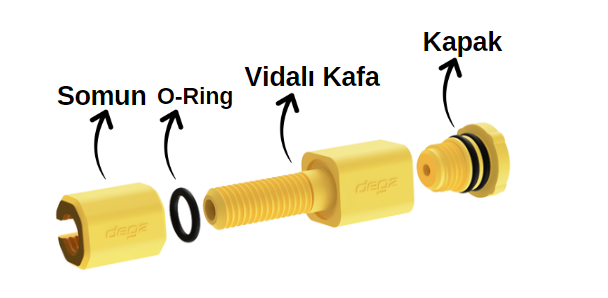

It is extremely easy to assemble! Insert the lid, attach the O-rings and tighten the nut. That’s it. That’s it. When the cable is passed through the body and reached the nut, a complete sealing is provided thanks to the added epoxy. With these simple steps, your penetrator is prepared to be resistant to underwater adventures.

Superior Material, Perfect Performance

Degz Neo Penetrator offers a lightweight but sturdy structure with a variety of plastic options. This structural element, which is further strengthened by epoxy application, allows underwater vehicles to perform at the highest level even in the most difficult tasks. Thanks to its innovative design, it maintains its reliability, providing a perfect sealing even in high-pressure deep water conditions.

The unique material composition of Degz Valve Penetrator stands out with its features that are non-corrosion and long-lasting use. This is a great advantage for equipment that operates especially in abrasive environments such as salt water. Also, thanks to its light weight, the penetrator does not have a negative effect on the maneuverability of the mounted vehicles, it will not cause any loss in speed and efficiency.

The combination of high-quality plastics and epoxy coating offers superior performance not only in terms of sealing and durability, but also in terms of aesthetics.

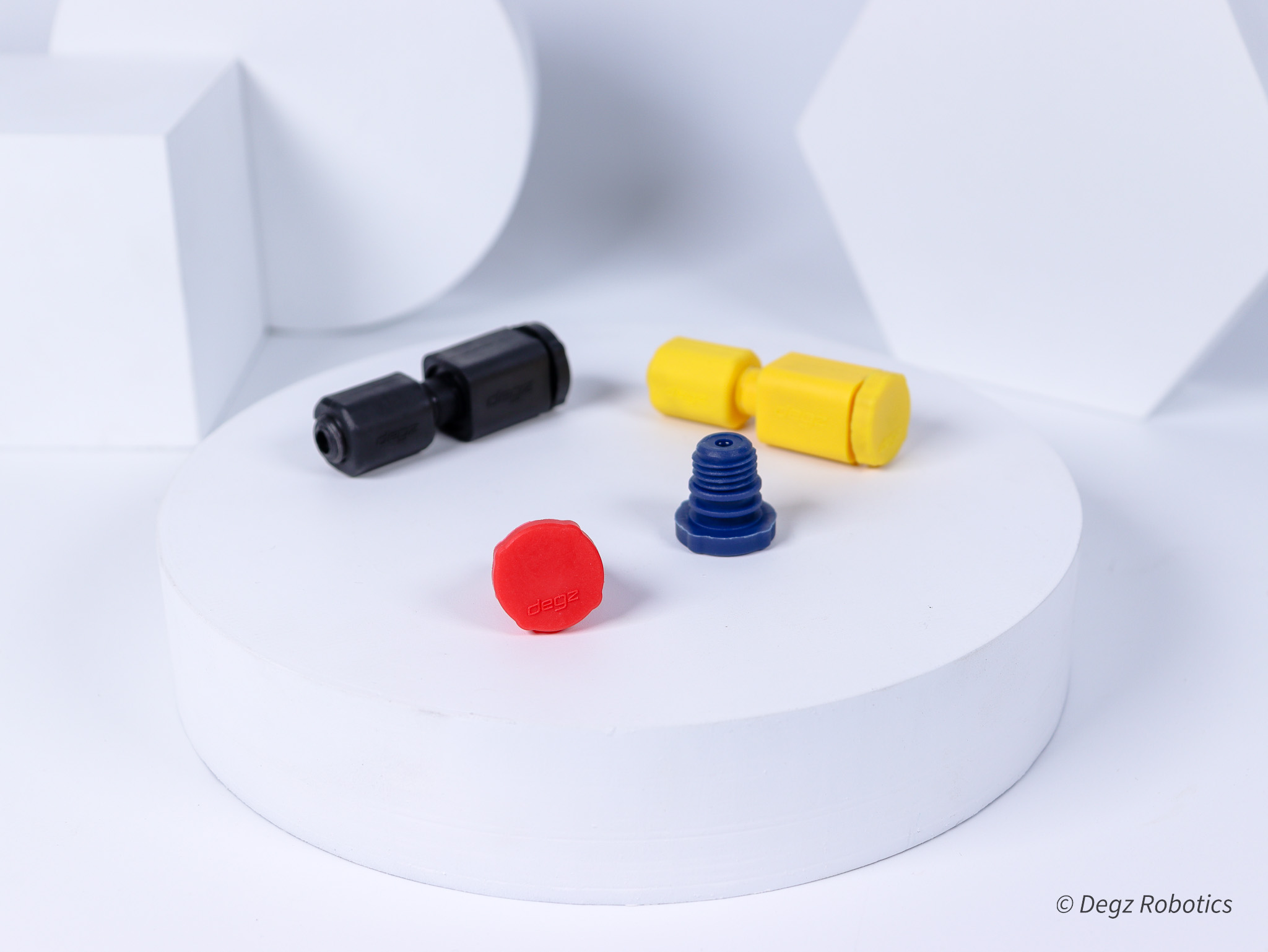

Nut allows the Penetrator to be safely installed in the chamber. After the screw head is passed through the hole of the hopper, it is screwed and compressed over the nut. This compression is critical to prevent the whole system from standing firmly in place and repelling water.

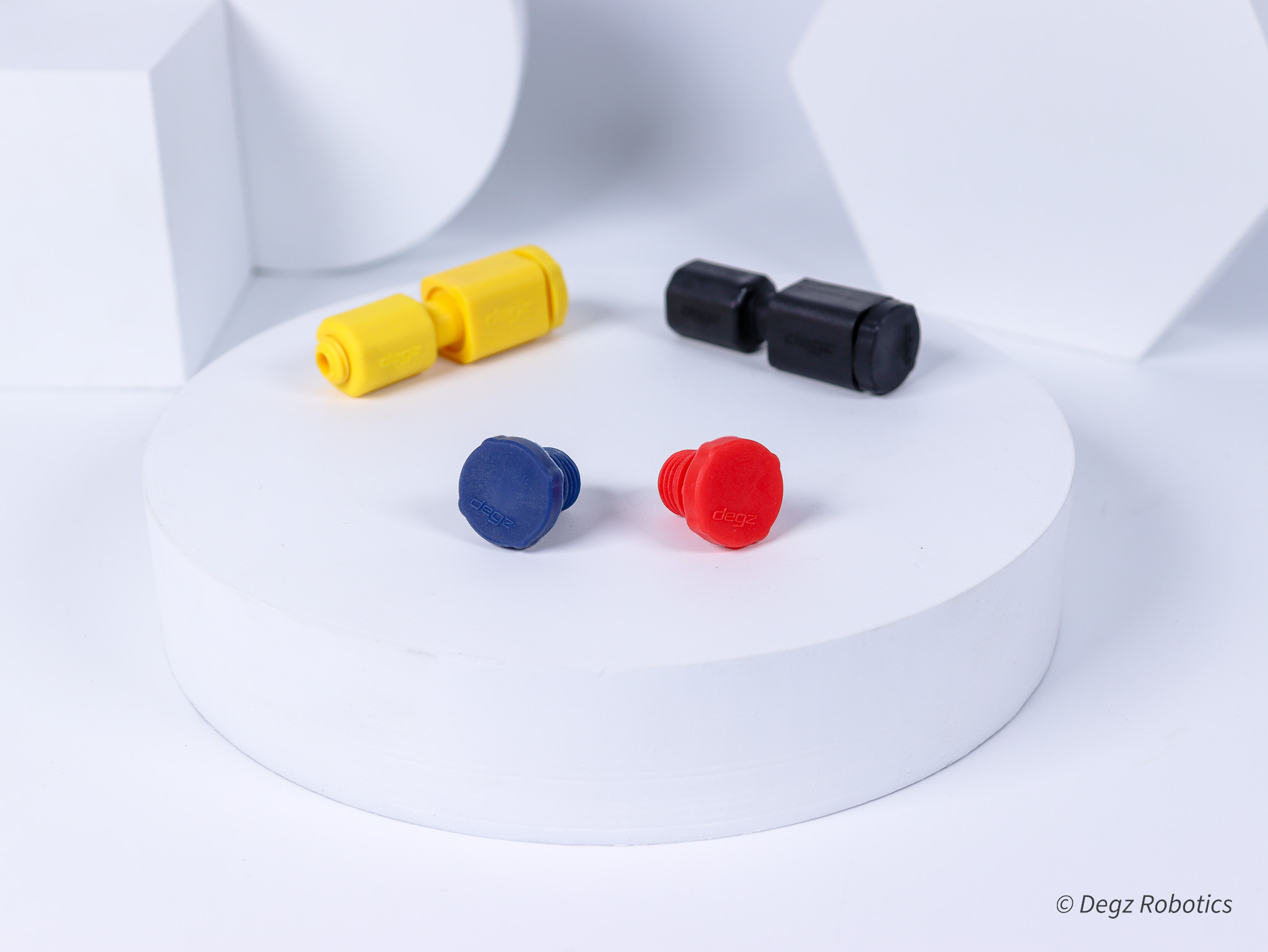

Screw Head is main section of the valve transferring air and holding parts together. This screw head is connected to place with the o ring to form the first sealing layer. The nut is attached to head o compress the o ring and fix the head in place. Then the cap is screwed to the top to ensure waterproofing. This method maximizes both mechanical stability and sealing against underwater pressures.

Cover is the part that activates the pressure relief function of the penetrator system. After screwing the cap, pressured o rings form a strong barrier that prevents water from infiltrating the interior.