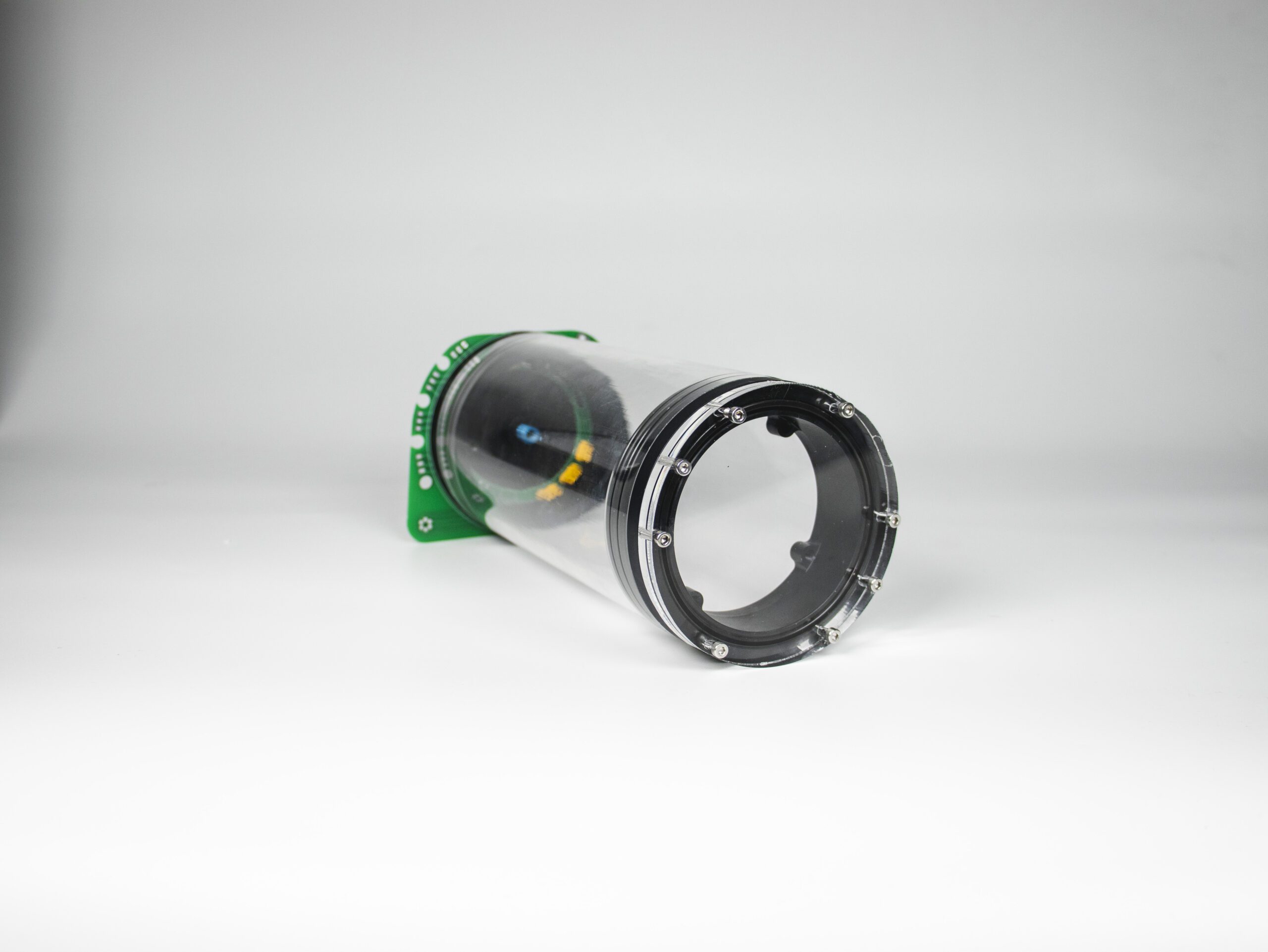

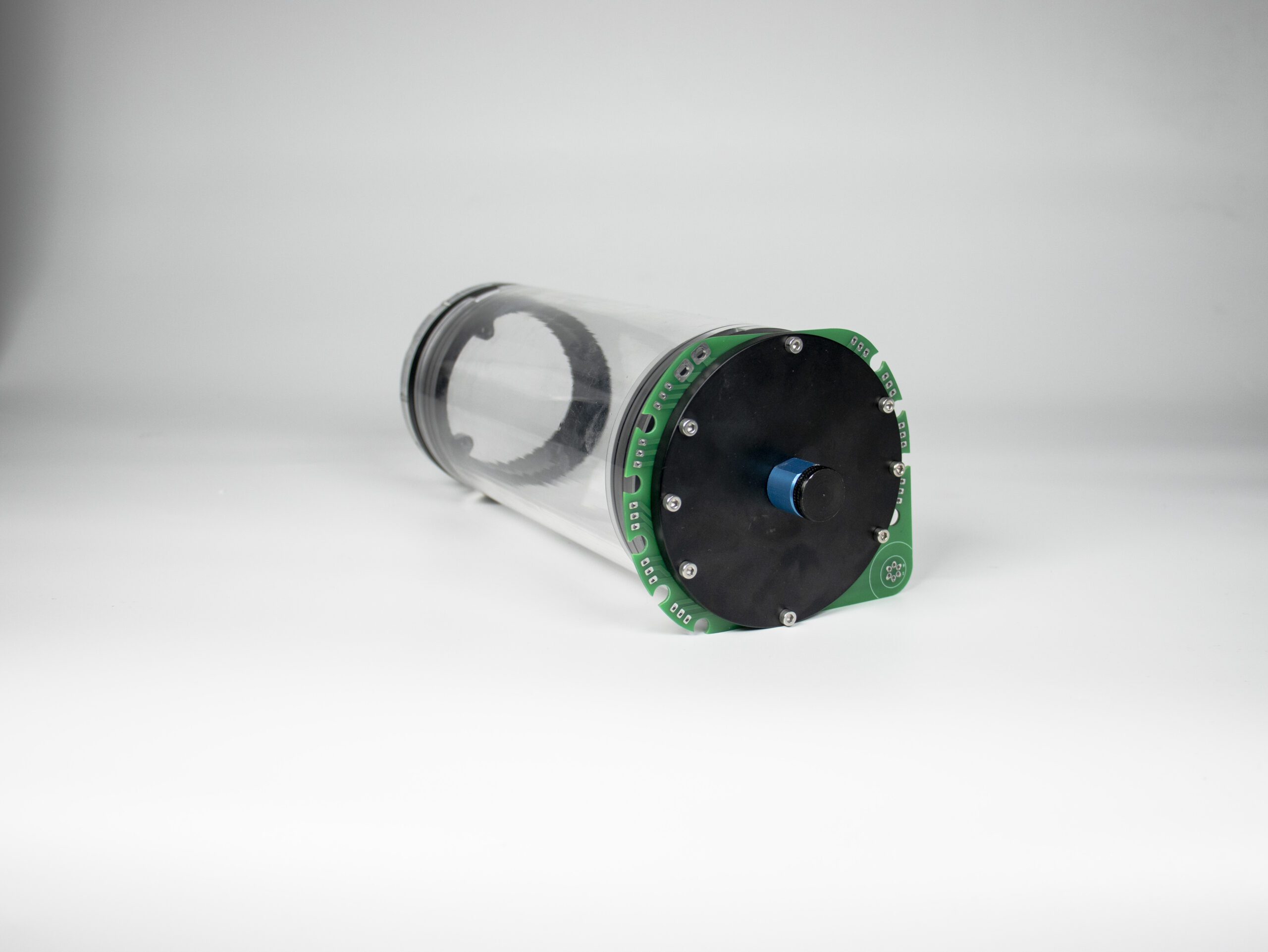

H-100 Subsea Watertight Enclosure

H-100 Underwater Enclosure was designed with the experience of a successful enclosure series and equipped with additional features specific to your underwater projects. Details such as the redesigned PCB connector set, precision machined 0-ring interfaces, special lock design, and designated guides for the penetrator hole make this enclosure unrivalled in terms of ease of handlin and durability. Its technical features include elements such as inner diameter, outer diameter, material suitable for use in salt water, and patented transfer technology.

- Redesigned PCB connector assembly for ease of handling

- Special lock design for preventing the end cap or flange flag from being rotated

- Preset guides for easy penetrator hole drilling

Technical Details

- Inner Diameter: 90mm

- Outer Diameter: 100mm

- Suitable for salt water application

- Anodized aluminium and chrome material

- 150 – 200 maximum depth rating*

- Patented transmission technology

- Fewer seals (4x on each cap including PCB)

- outlets up to 8 motos (24 Pin) / 6pin communication / 3x (6 pin) switching channel line

*The depth ratings for cast acrylic components vary depending on the length of the acrylic tube

Contents

- Acrylic tube

- H100 Flange (2x)

- H100 Cap

- H100 Front Acrylic Cap

- H100 Cable Transfer Board

- Cable penetrator

- 3×82 O-ring (7x)

- 3ML Special Grease

- M3x16 Imbus bolt (16x)

Weight

Front Aluminium Flange – 290g

Back Aluminium Flange – 300g

250mm acrylic tube – 430g

300mm acrylic tube – 520g

350mm acrylic tube – 610g

Assembly manual

When first preparing the chamber for use, all o-ring seals must be lubricated with silicone liquid grease. This will prevent the wear of the seals by reducing friction, especially in the parts in contact with the acrylic. Silicone grease will ensure that the O-Ring fits the surface perfectly.

When tightening the screws of the chamber, make sure that all screws are tightened at the same rate. Then, be sure to check the position of the cover. If there is any slant on the cover, open it again and check if there is an object stuck in there. It is easier to visually check this on the front cover. Check how much the gaskets are crushed when tightening the screws.

Things to pay attention

Protect the enclosure from dropping on the ground, impact with hard objects, high temperatures, and pinching. When you add a battery into the chamber, never secure the lids so that they cannot be opened in case of explosion. Without covering the transmitter card, you can test it in fresh water for not more than half an hour with devices that do not operate at high current, but after the tests, remove the outer cover on the back ring, dry it, and cover the surface. Chlorinated water can damage aluminium, so avoid long-term use in pools. After placing the container in salt water, rinse it with fresh water after each use to ensure removal of remaining salt on the surface.

For design files you can click here.

H-100 Underwater Watertight Enclosure REVIEW

In this video, we talk about the details of the H-100 Underwater Enclosure.

Reviews

There are no reviews yet.